Industrial Pollution and Its Impact on Solar Panel Performance

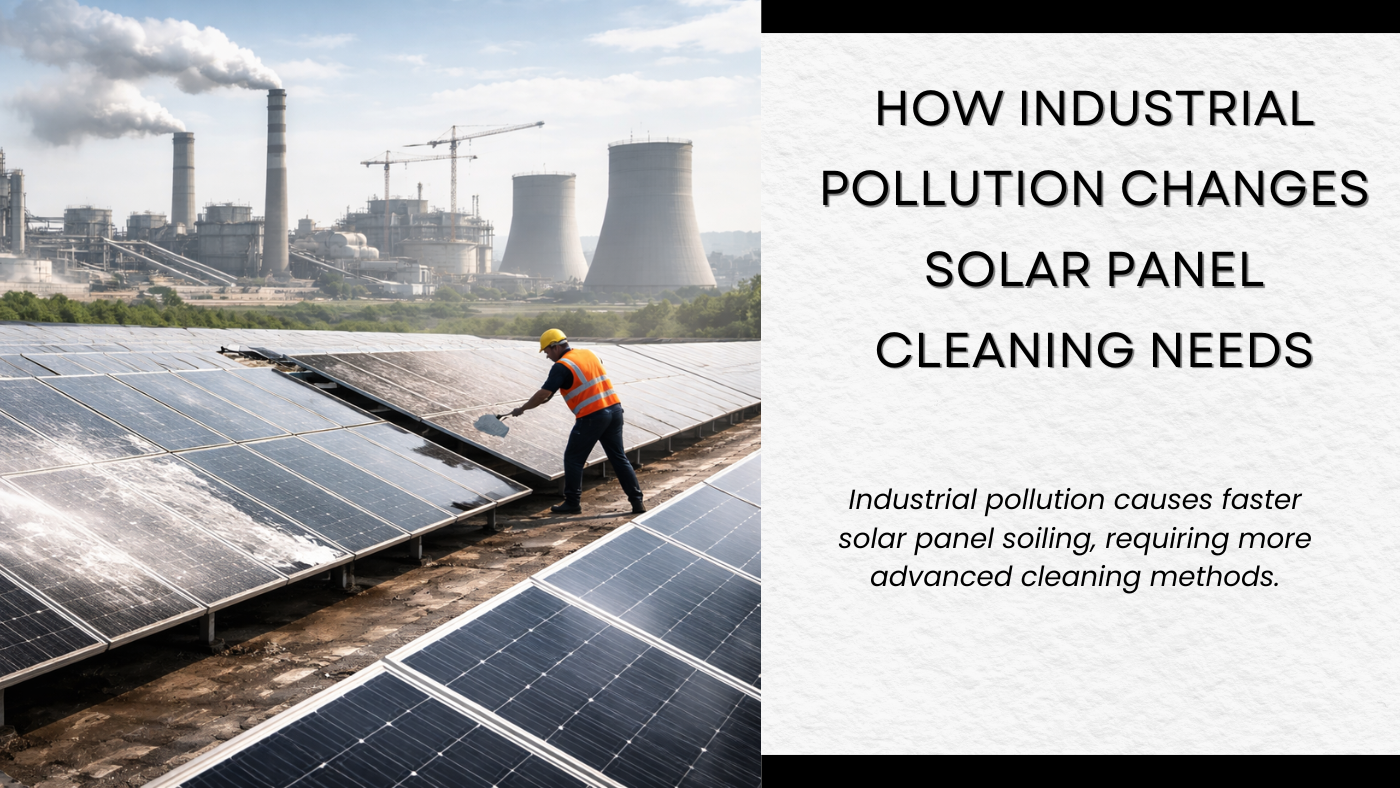

Rapid industrialization has led to the expansion of manufacturing hubs, cement plants, power stations, and industrial corridors across many regions. At the same time, solar installations are increasingly being set up near these zones to meet growing energy demands, making solar panel cleaning a critical maintenance activity in industrial environments.

While solar energy remains clean and sustainable, the surrounding environment plays a major role in how efficiently panels operate. In industrial areas, standard solar panel maintenance practices often fall short. Pollutants behave differently from normal dust, making conventional cleaning methods less effective and sometimes even harmful.

Understanding how industrial pollution affects solar panels is essential for adapting cleaning strategies and protecting long-term performance.

What Is Industrial Pollution and How Does It Affect Solar Panels?

Industrial pollution refers to airborne and surface-level contaminants released during manufacturing, construction, and processing activities.

Common industrial pollutants include:

- Cement and construction dust

- Smoke, soot, and smog particles

- Chemical vapors and residues

- Metallic and abrasive micro-particles

Unlike household or natural dust, these pollutants tend to bond strongly with solar panel surfaces. Over time, this leads to stubborn layers of contamination, a condition known as solar panel soiling, which significantly reduces energy output.

Common Types of Industrial Contaminants on Solar Panels

Industrial environments introduce a wide range of contaminants, each presenting unique solar panel cleaning challenges:

Cement and construction dust

Fine cement particles harden when mixed with moisture, forming crust-like layers that are difficult to remove.

Industrial smoke and smog

Carbon-based particles from furnaces and exhaust systems create dark films that block sunlight.

Chemical vapors and sticky residues

Certain industries release vapors that condense into oily or sticky deposits on panel glass.

Metallic and abrasive particles

Microscopic metal fragments can scratch surfaces during cleaning if not handled correctly.

How Industrial Pollution Alters Solar Cleaning Requirements

Solar panel cleaning in industrial areas requires a fundamentally different approach.

Key changes include:

- Higher cleaning frequency due to rapid contamination buildup

- Deeper cleaning to remove bonded and sticky pollutants

- Greater surface protection to prevent abrasion and coating damage

Industrial solar panel cleaning is not just about appearance—it directly impacts performance, safety, and system lifespan.

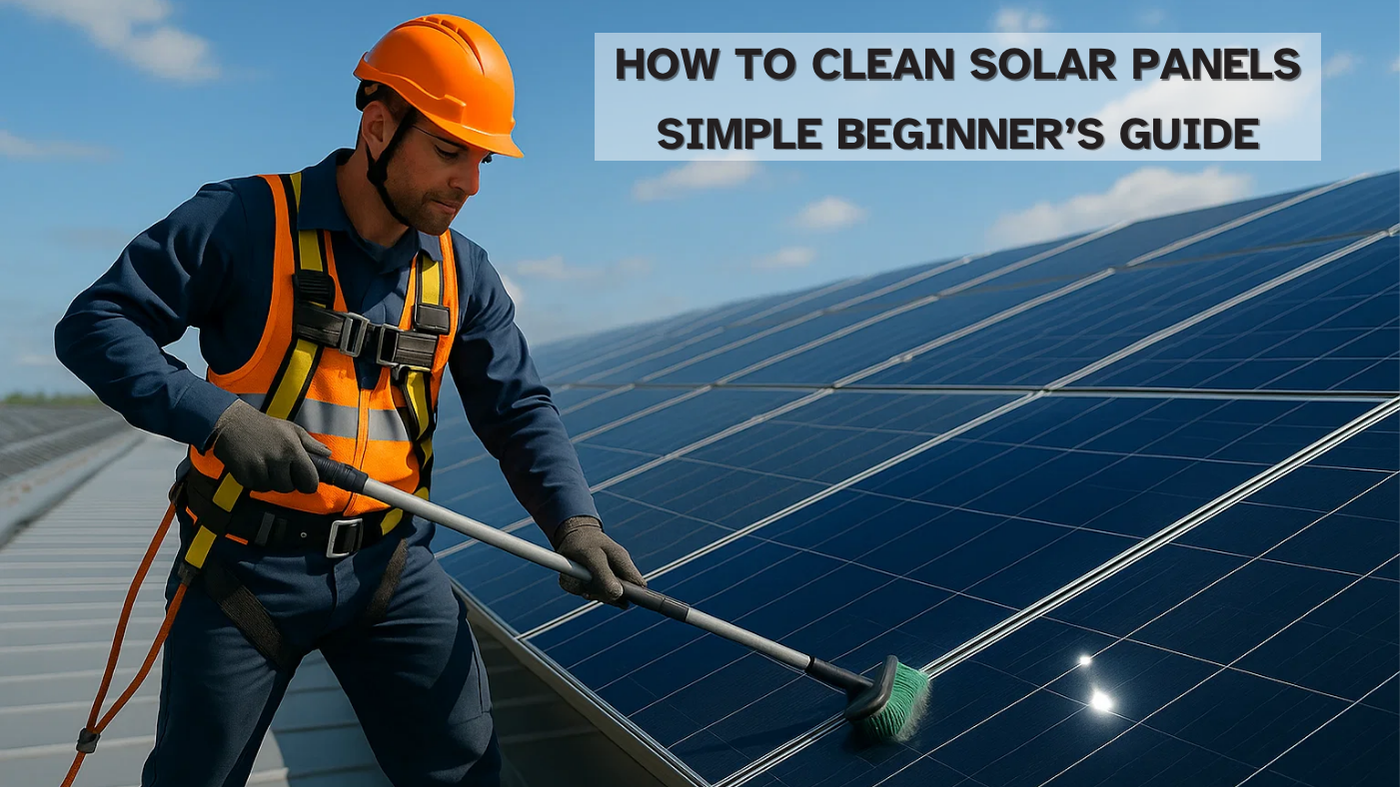

Limitations of Water-Only Cleaning in Industrial Zones

Water-only cleaning methods struggle in polluted environments.

Major limitations include:

- Inability to dissolve oily or chemical residues

- Streaking caused by hard water minerals

- Partial cleaning that leaves invisible films behind

These residues attract more pollutants, leading to faster re-soiling and increasing maintenance costs over time. For effective solar panel maintenance in industrial zones, water alone is rarely sufficient.

Role of Solar Panel Cleaning Chemicals in Polluted Environments

Specialized solar panel cleaning chemicals are designed to address industrial contamination safely.

How they help:

- Break down cement dust, soot, and chemical films

- Reduce the need for aggressive scrubbing

- Enable residue-free rinsing

Heavy-duty solar panel cleaning solutions work chemically rather than mechanically, minimizing stress on the panel surface while delivering deeper cleaning results.

Impact of Industrial Pollution on ARC Coatings and Glass Surfaces

Industrial pollutants pose a serious threat to solar panel ARC coatings (anti-reflective coatings).

Long-term risks include:

- Gradual chemical degradation of ARC layers

- Micro-scratches caused by abrasive particles

- Uneven heating and hotspot formation

Without protective cleaning practices, damage to ARC coatings leads to permanent efficiency loss, making proper maintenance essential in polluted locations.

Cleaning Challenges for Solar Farms and Power Plants Near Industries

Utility-scale installations near industrial areas face additional challenges:

- Managing contamination across thousands of panels

- Minimizing downtime during cleaning operations

- Maintaining consistent output for grid commitments

In such settings, professional solar panel cleaning solutions that are scalable, efficient, and surface-safe become a necessity rather than an option.

Eco-Friendly Cleaning Solutions for Industrial Solar Installations

Sustainability remains important even in industrial cleaning.

Eco-friendly solar panel cleaning chemicals offer:

- Biodegradable and non-corrosive formulations

- Reduced water consumption per cleaning cycle

- Lower environmental impact around industrial zones

These solutions balance performance with responsibility, ensuring effective cleaning without adding to environmental burden.

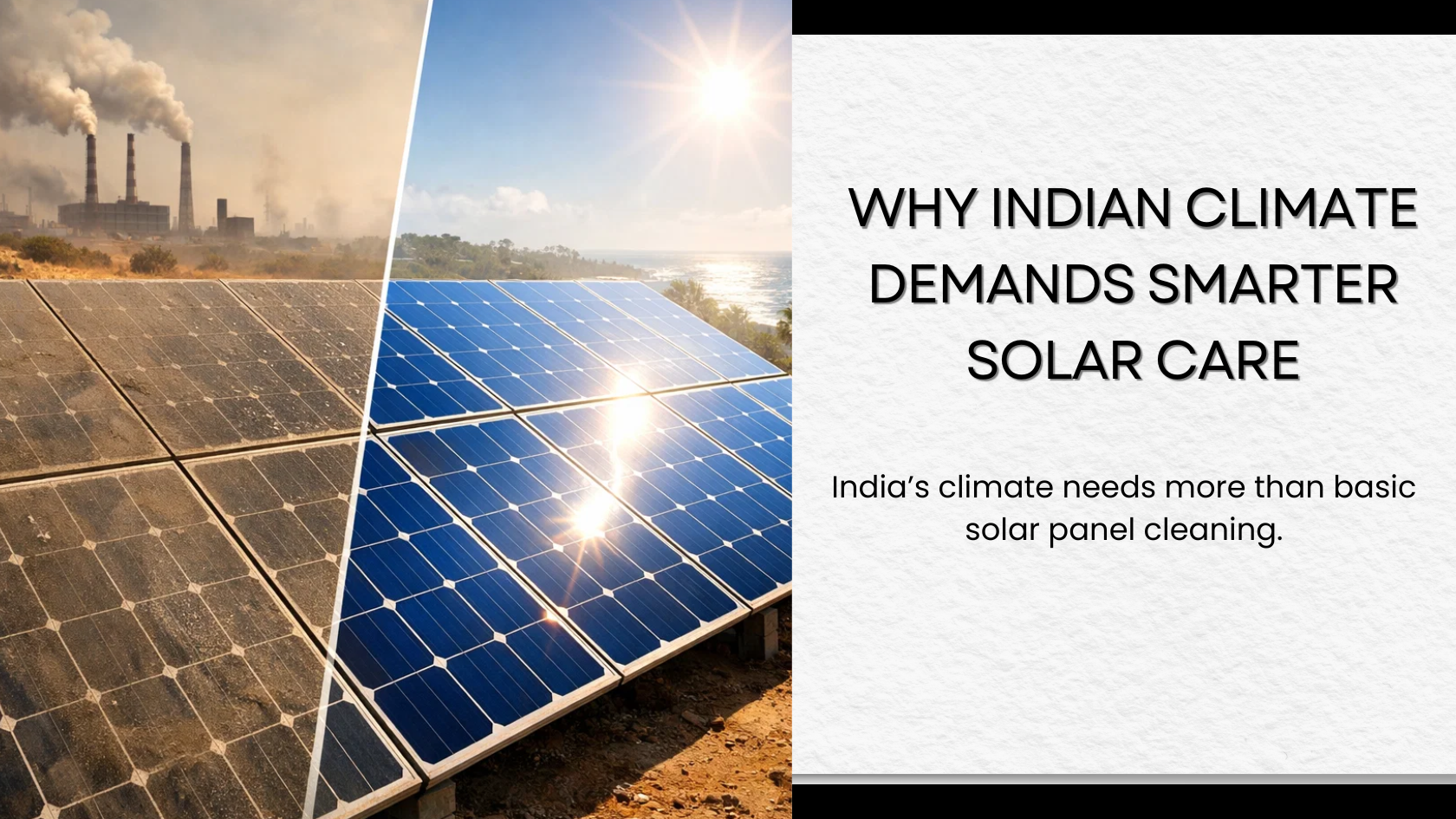

Choosing the Right Cleaning Strategy for Industrial Locations

An effective industrial cleaning strategy depends on:

- Type and intensity of pollution

- Proximity to factories or construction zones

- Size and configuration of the solar system

Residential systems may tolerate basic methods, but industrial setups require expert-guided solar panel cleaning solutions tailored to local conditions.

Adapting Solar Panel Cleaning Strategies for Industrial Environments

Industrial pollution significantly alters the way solar panels must be maintained to deliver consistent performance. In polluted zones, contaminants such as cement dust, chemical residues, soot, and abrasive particles accumulate faster and adhere more strongly than ordinary dust. These conditions make conventional solar panel cleaning methods ineffective and increase the risk of surface damage if improper techniques are used.

By implementing proactive and specialized solar panel cleaning solutions, operators can effectively protect panel glass and ARC coatings, minimize efficiency losses, and extend system lifespan. Strategic solar panel maintenance in industrial areas not only ensures stable energy output but also reduces long-term operational costs and unplanned downtime. In high-pollution environments, adopting advanced, pollution-specific solar panel cleaning practices is essential for preserving performance, protecting investments, and maintaining reliable power generation.

Frequently Asked Questions on Industrial Solar Panel Cleaning

1. How does industrial pollution affect solar panel efficiency?

Industrial pollution deposits cement dust, soot, chemical residues, and metallic particles on solar panels. These contaminants block sunlight, increase surface heat, and reduce power generation efficiency over time.

2. Why is solar panel cleaning more difficult in industrial areas?

Unlike normal dust, industrial pollutants bond tightly with panel glass, often forming sticky or hardened layers that cannot be removed using basic water cleaning methods.

3. What types of industrial contaminants cause solar panel soiling?

Common contaminants include cement dust, industrial smoke, smog particles, chemical vapors, and metallic micro-particles, all of which accelerate solar panel soiling.

4. Can industrial pollution damage solar panel glass or coatings?

Yes. Prolonged exposure to abrasive and chemical pollutants can degrade anti-reflective (ARC) coatings, cause micro-scratches, and lead to permanent efficiency loss.

5. What is the best solar panel cleaning solution for industrial environments?

Specialized solar panel cleaning solutions formulated for industrial pollution are ideal, as they dissolve cement dust, soot, and chemical residues without damaging glass or ARC coatings.

6. Are solar panel cleaning chemicals safe for long-term use?

High-quality, eco-friendly solar panel cleaning chemicals are non-corrosive, ARC-safe, and designed for repeated use without harming panel surfaces or reducing lifespan.

7. How often should solar panels be cleaned in industrial zones?

Cleaning frequency depends on pollution intensity, but industrial solar installations typically require more frequent cleaning than residential systems to maintain optimal output.

8. Should industrial solar plants use professional cleaning services?

Yes. Professional solar panel cleaning services use advanced solutions and controlled methods that ensure deep cleaning, surface protection, and minimal downtime for large-scale installations.